Throughout his professional career Marcos Rupérez has participated in singular engineering projects mainly related to renewable energies, alternative mobility, sporting challenges, industrial design and competition. Below are some of the most relevant.

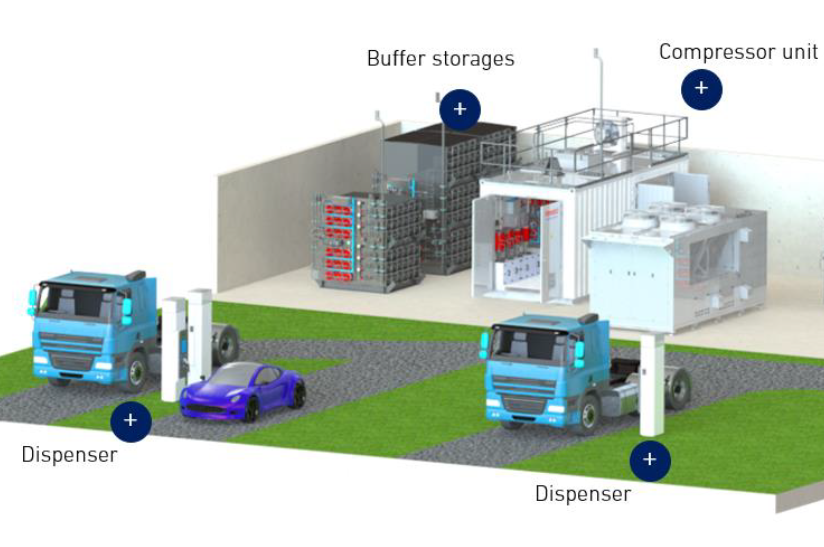

The Grupo Alonso logistics group considered converting 30 trucks (40-ton trailers) of its fleet to fuel cell trucks to be operated all together with the rest of its fleet. Marcos Rupérez was hired by Diverxia (one of the group’s companies) to promote said project and advise on its design and execution. The following tasks/functions were […]

The multinational CEMEX ventures hired Marcos Rupérez to evaluate different emerging companies in which they were planning to participate in their investment rounds. Based on this, we work continuously for them, evaluating the technical documentation of the different due diligences, carrying out techno-scientific calculations of their technologies, evaluating the real business potential, as well as […]

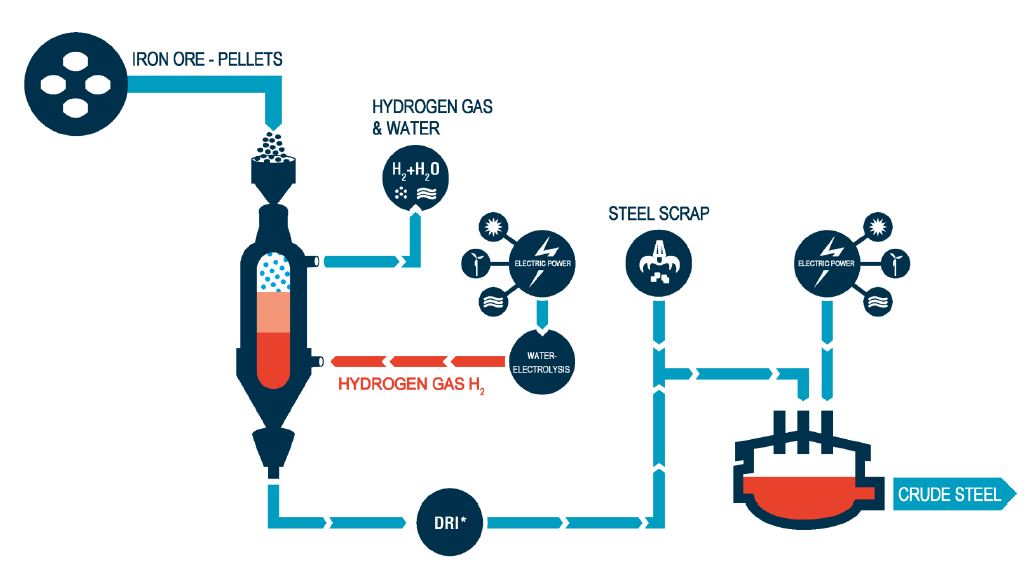

The company DIPROINDUCA, specialist in the circular economy of waste in the metallurgical sector, hired Marcos Rupérez to evaluate the implementation and investment in companies related to the reduction of iron ore without CO2 emissions. Technology evaluation work was carried out throughout its production cycle. The technology replaces carbon or natural gas (common reducers) with […]

The ‘Acciona 100% EcoPowered’, was the first zero-emission electric car that participated in the Dakar rally (http://www.dakar.com/). The vehicle was driven by a synchronous electric motor of 220 kW, a power equivalent to 300 horsepower, was piloted by Albert Bosch and Agustin Paya. The objective was to achieve optimal integration of a full electric propulsion […]

Our costumer Juan Yacht Design (one of the leading designers in the world of competitive sailing, participating in America`s cup) commissioned us to study the feasibility of power with hydrogen fuel cell system the yacht to one of its customers in Dubai. The aim of the design was to achieve the maximum possible autonomy in […]

The great challenge of ACCIONA 100% EcoPowered was to be the first modern race boat that goes around the world without an internal combustion engine to charge the batteries. This is the challenge I was held within the framework of the toughest sailing competition in the world, around the world solo without climbing, the Vendee […]

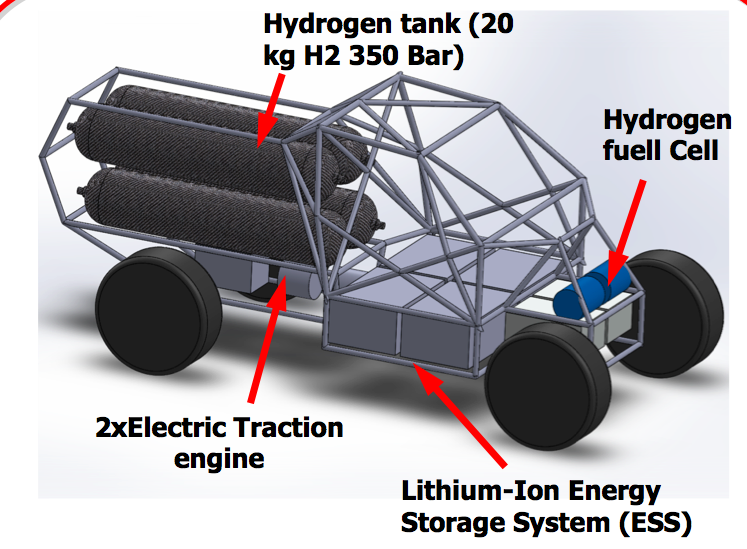

The customer required the design of a hydrogen fuel cell 4×4 racing car. This car should have a range of 900km without any hydrogen recharge. The Quionne team designs a vehicle consisting of two fuel cell of 30kW power each one. These fuel cells were feed with hydrogen by four large high pressure carbon fiber […]

A conceptual engineering was carried out on the development possibilities of Hydrogen technology for the oceanic research platform PLOCAN. In this study, the potential of installing electrolyzers as well as hydrogen supply systems for Ships on the platform itself were analyzed.

Marcos Rupérez participates as an external consultant in the Shinefleet project where a heavy duty hydrogen fuel cell truck for transporting goods by road is being built. Marcos works as an external party to support the Tecnalia Automotive team, designing both the piping system for recharging, storing and supplying hydrogen to the battery. As well as […]

Formula Zero was the first international competition for hydrogen and fuel cell vehicles. Marcos Rupérez participated as design engineer in the team unizartech2 that was second in the season 2009 with a vehicle entirely designed and assisted in race by the equipment. https://unizartech2.wordpress.com/

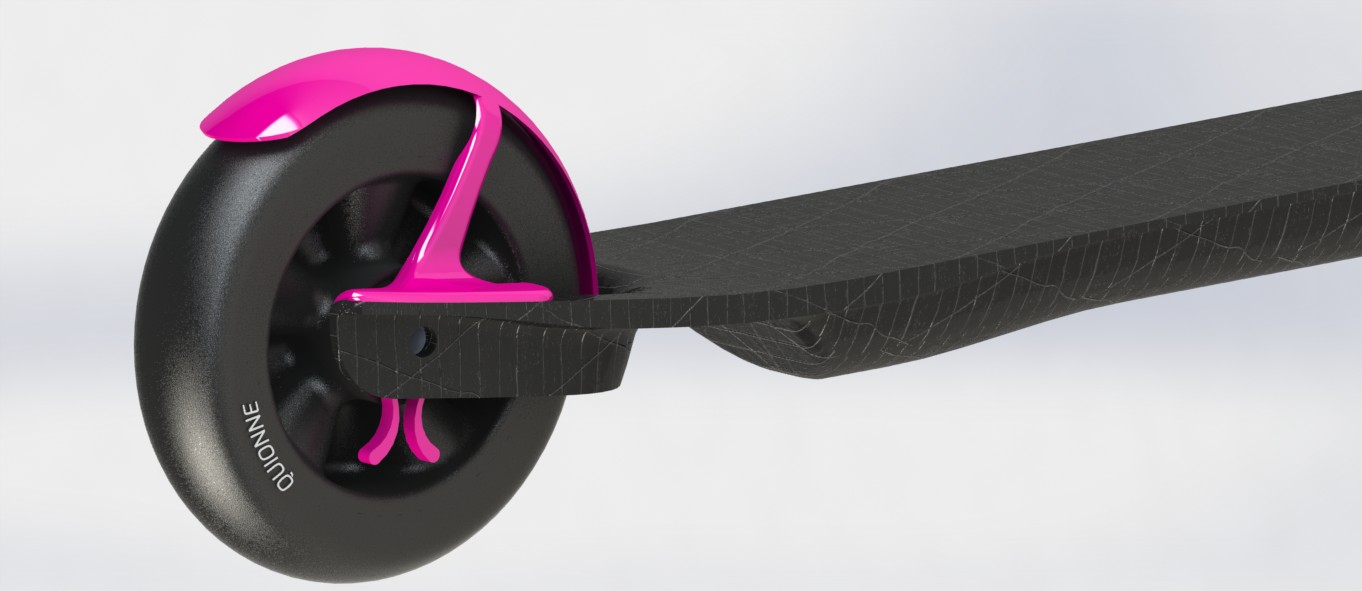

Quionne team is expert in carbon fiber parts and carbon fiber production processes. Here our main carbon fiber project of is exposed, it is a complete product development process where we have done the design, numerous prototypes by different production methods, a intensive prototype testing and also the development of a process to achieving […]

The engineers team of Quionne design a battery pack with high security and robustness to be installed in electric vehicle prototype. The batteries were designed based on prismatic modules (LYP) achieving a total capacity of 36KWh. The aim was to achieve a robust pack to be installed and swaped on vehicles in difficult conditions with […]

Starting from the need to manufacture a piece in the prototype stage. An assessment of the processes and positions needed for the manufacture is perform. The objective is to achieve the minimal impact of labor possible in the final cost of the piece was made. Some piece design modifications were suggested that was not changing […]

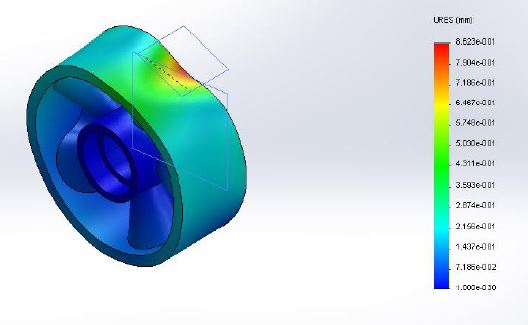

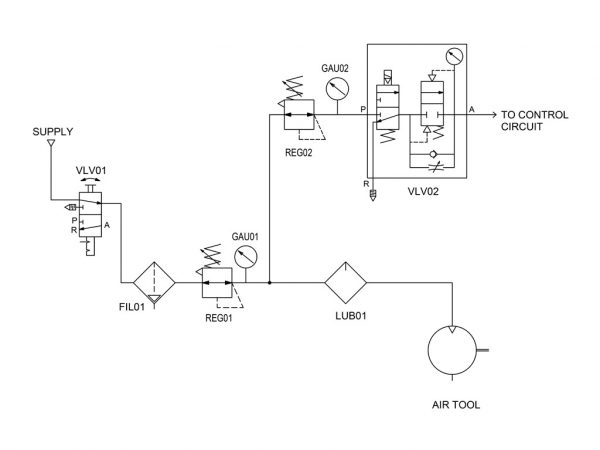

Thermal management system and fluids for industrial production process are conducted. In this process pumps, heaters and equipment required for the thermal suitability of the process are defined. The same design process is repeated for pressure system, defining the injection pressures, piping, valves, compression and injection machines. Hydraulic and pneumatic actuators operating certain components of […]

Within the wide range of manufacturing carbon fiber processes the Quionne team has high experience in high temperature, and high pressure RTM (Resin Transfer Moulding). This type of process that achieves short cycle time with high quality parts, we manage to do good pieces with some minute cycles. Thus it is usable for manufacturing parts […]

Quionne team has designed several pieces of plastic for internal and external projects. The design process start with a detected necessity. It is evaluated and it is decided which material material and manufacturing process is the best taking into account the necessities. Case it is decided that the best material to realize it is plastic. […]

The project consisted on the design and operation of a system for recharging a swappable battery packs of an electric vehicle during a long route. The aim was to ensure that the electric vehicle could make 1000km a day on consecutive days with no longer stops than 30 minutes every battery swap or charge. First […]

Marcos Rupérez, in the summer of 2020, I made a solidarity route by bike with Pedro García and José Luis Pina, all of them entrepreneurs and businessmen. Together they made a route of 1200 km and 33 days by bicycle through the depopulated Huesca, with the intention of carrying out a business analysis on the […]