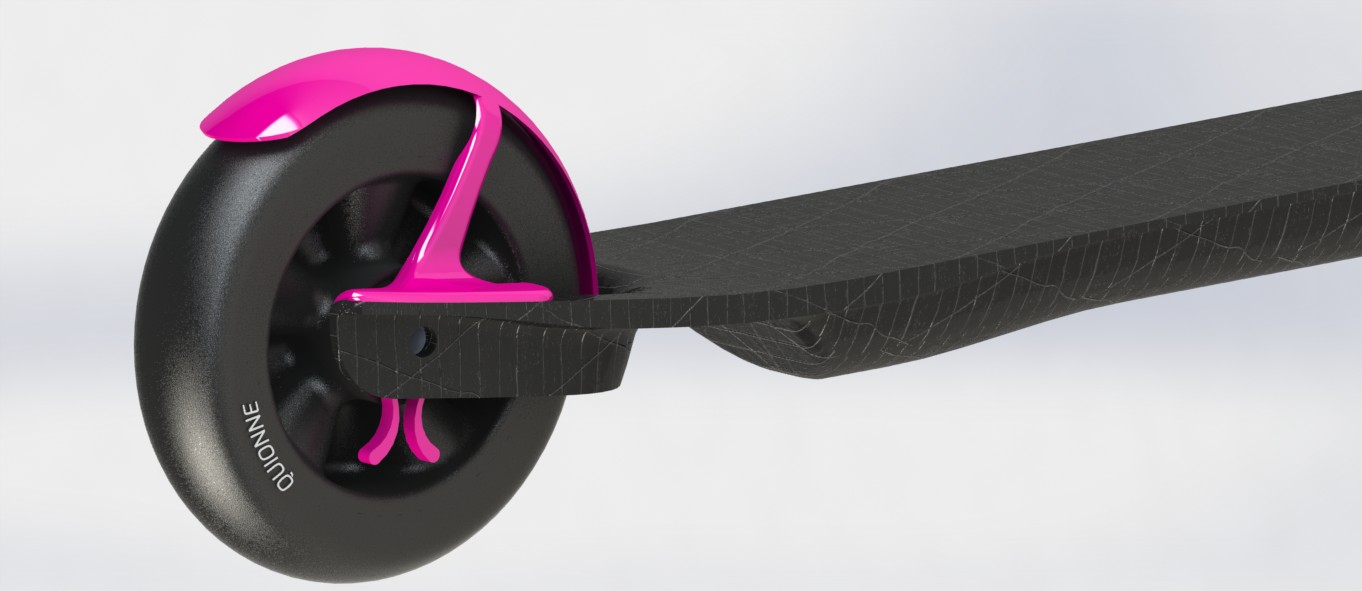

Quionne team has designed several pieces of plastic for internal and external projects. The design process start with a detected necessity. It is evaluated and it is decided which material material and manufacturing process is the best taking into account the necessities. Case it is decided that the best material to realize it is plastic. First we make a 3D design of the piece and also a prototype on carbon fiber by hand is necessary. Later the piece is printed in 3D and is tested on real environment (can be printed on 3D also in metallic materials).

Once the 3d printed piece is tested, some improvements are done and the piece is reprinted and tested another time, this process is repeated until the piece results are satisfactory.

Finally, the production cost and investment is evaluated and the plastic injection mold is designed and manufactured with the assistance of our partner Grávalos. For large parts we use plastic foam blocks and mechanize.

Grávalos S.A. is a company with extensive experience in production and plastic injection operating since 1946 for clients such as the Bosch group. Ramiro Simon is the Head of the R&D department and a technical reference in the world of plastic production. In Quionne we work closely with the department in R & D developments for our projects relying on his experience.